AIPCon 8 American Airlines: Transforming Network Planning for Aviation

AIPCon 8 Part 3

American Airlines used AIPCon 8 to show something rare in aviation tech talks: not just a vision slide, but a concrete planning system—Vector—that is already changing how the world’s largest airline schedules and operates flights. Below is a practitioner-oriented walk-through of what Vector is, the problems it targets, and how its technical components fit together to produce measurably better schedules.

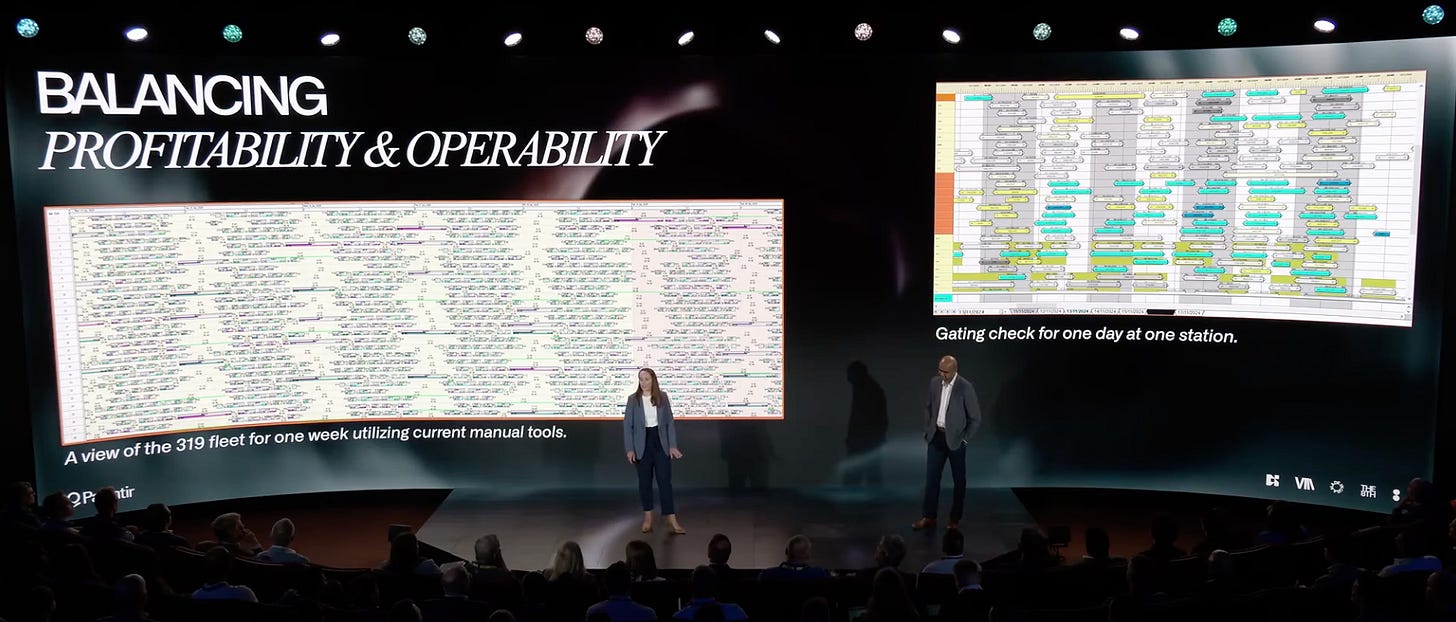

Why Network Planning Needed a Rethink

American Airlines runs a staggering operation: ~220 million passengers annually, ~6,500 flights per day, supported by tens of thousands of pilots, flight attendants, airport staff, and mechanics. Even getting one flight pushed back on time depends on months of upstream planning—aircraft assignment, crew pairing and legal rest, gates, maintenance turn times, fueling, baggage, and dispatch. Historically, much of this was coordinated through manual, sequential, and siloed processes: spreadsheets, email attachments, and team-specific tools. That approach struggles under real-world volatility, where demand shifts and operational constraints evolve continuously.

The result: by the time one team identifies an improvement, it may collide with another team’s constraints (e.g., “fixing” a crew issue introduces a maintenance conflict). Optimization opportunities are routinely obscured by process friction.

Vector: An Integrated Planning Surface

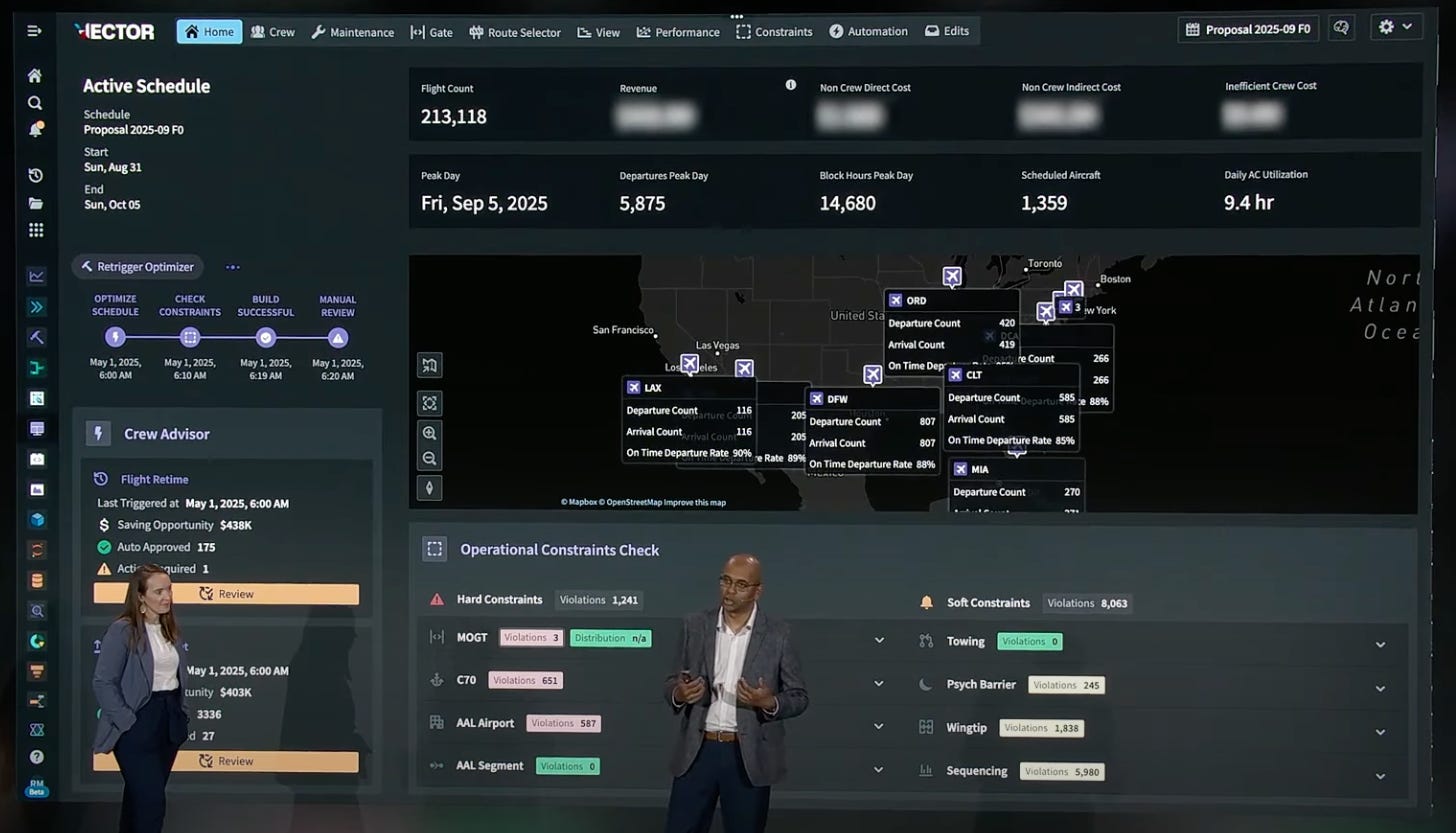

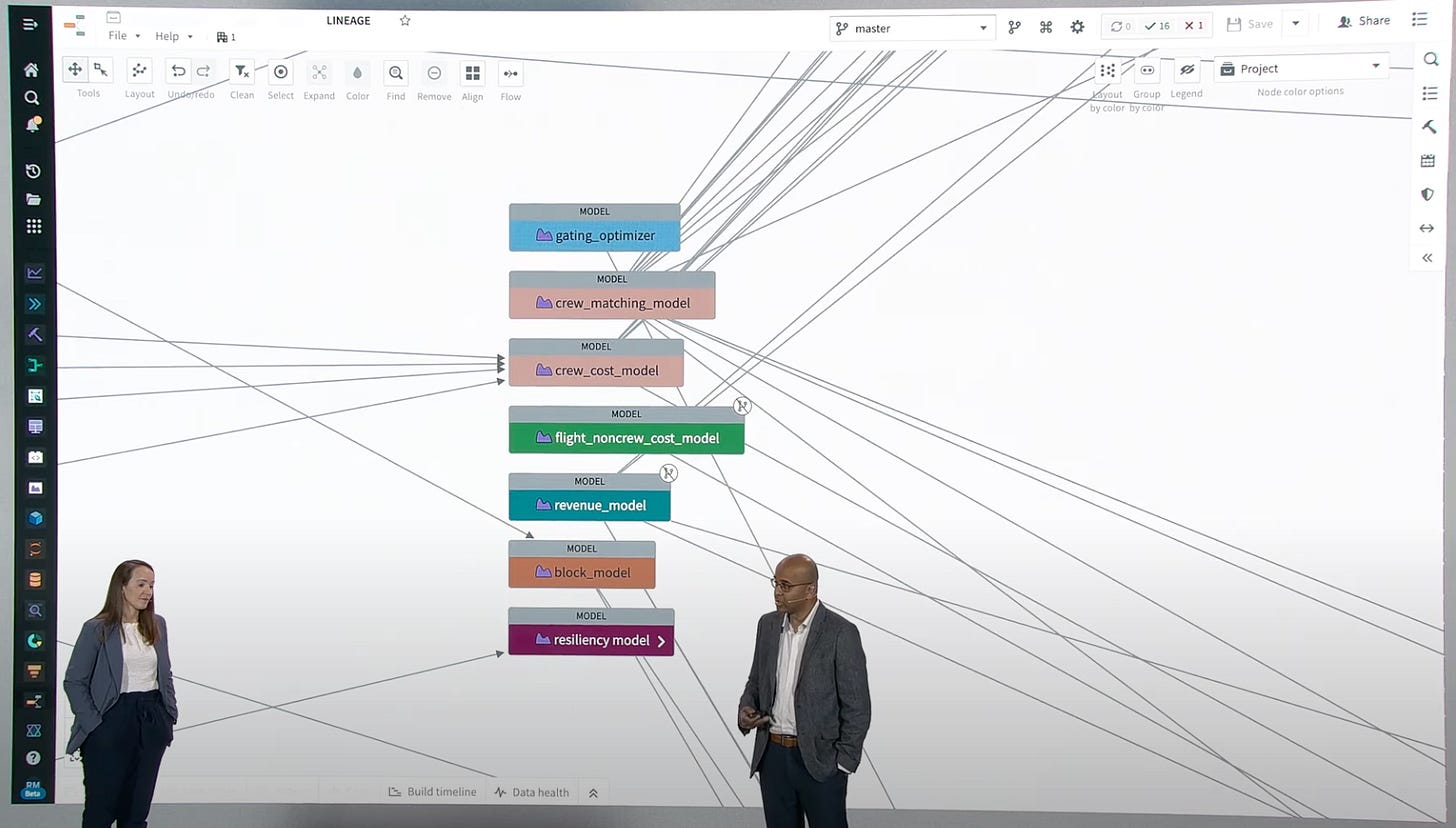

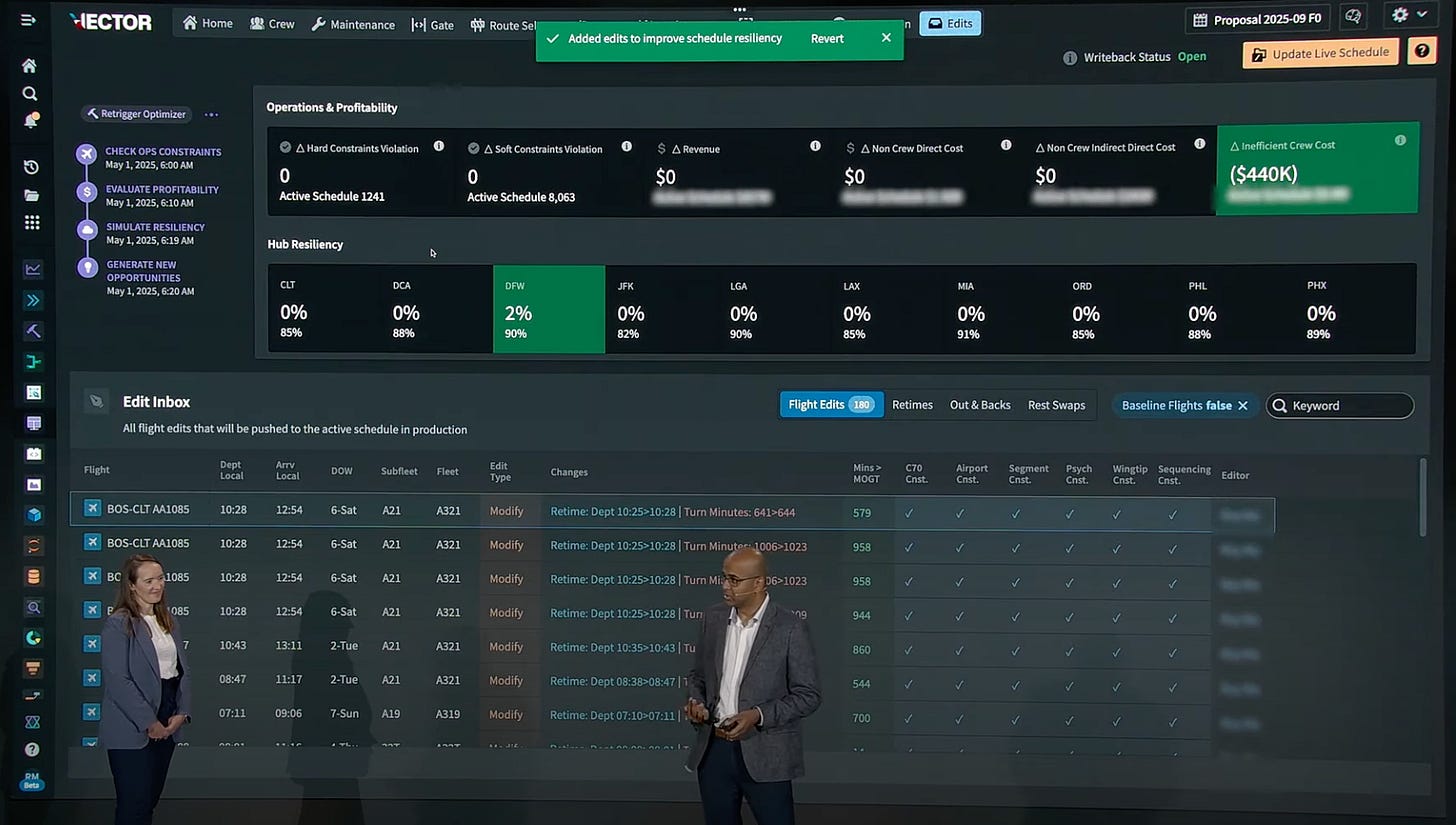

Vector sits on top of American’s data and workflow fabric as an integrated planning environment. Built on Palantir Foundry, it links network planning (the schedule “blueprint”) with operational planning (crew, gates, maintenance, ground equipment, materials), surfacing issues and opportunities continuously rather than in periodic hand-offs. In its first year of adoption, the initiative has already yielded tens of millions of dollars in value—evidence that coordination costs were masking a large optimization frontier.

At a glance, the Vector interface exposes KPI panels (to orient schedulers on reliability and profitability targets) and a left-hand Advisor module that proactively pushes recommended investigations and edits. Instead of hunting through thousands of rotations and duty periods, planners receive prioritized “cards” that say, in effect, ‘here is a likely inefficiency and a proposed fix.’

The Problems Vector Solves

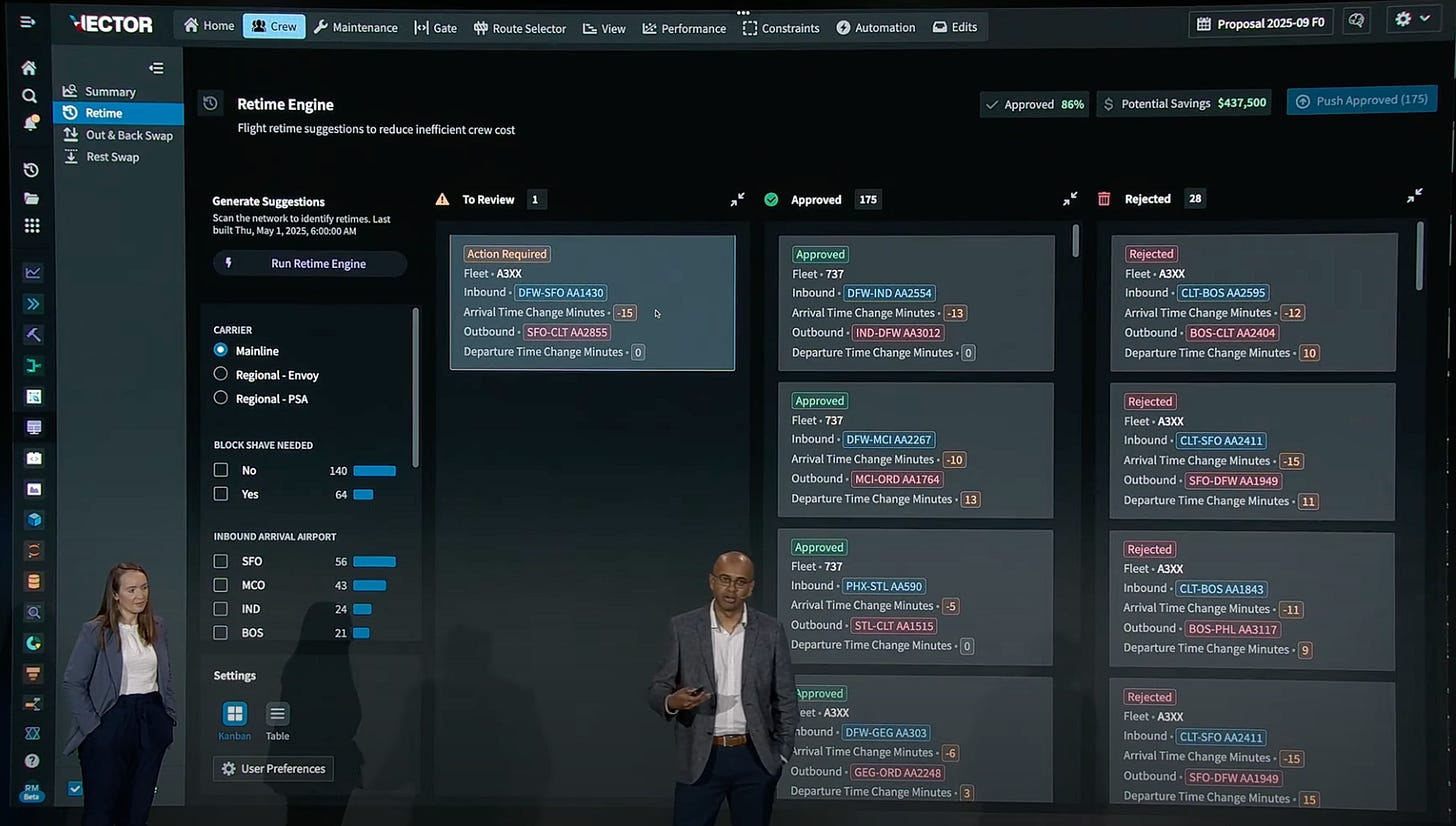

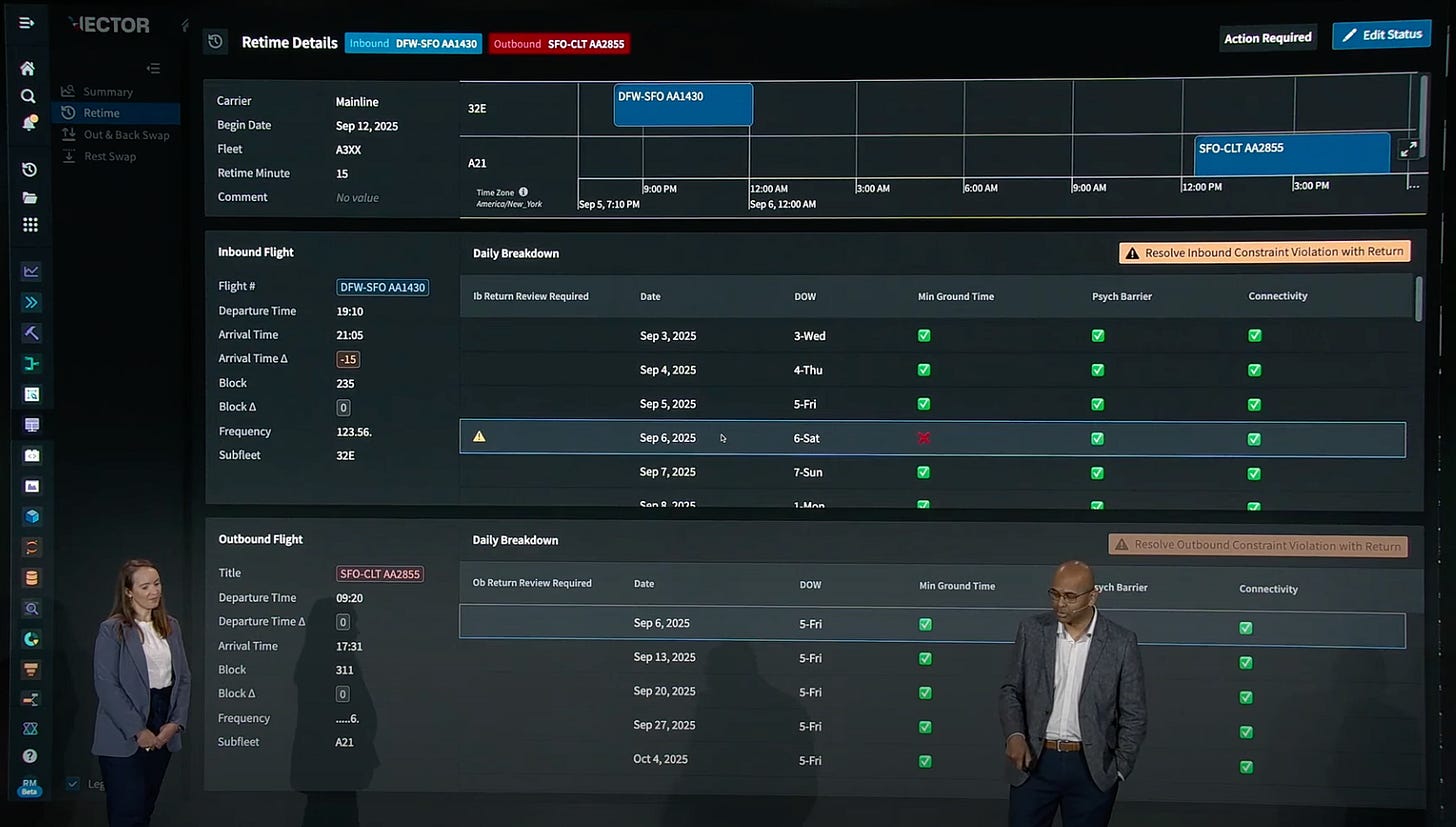

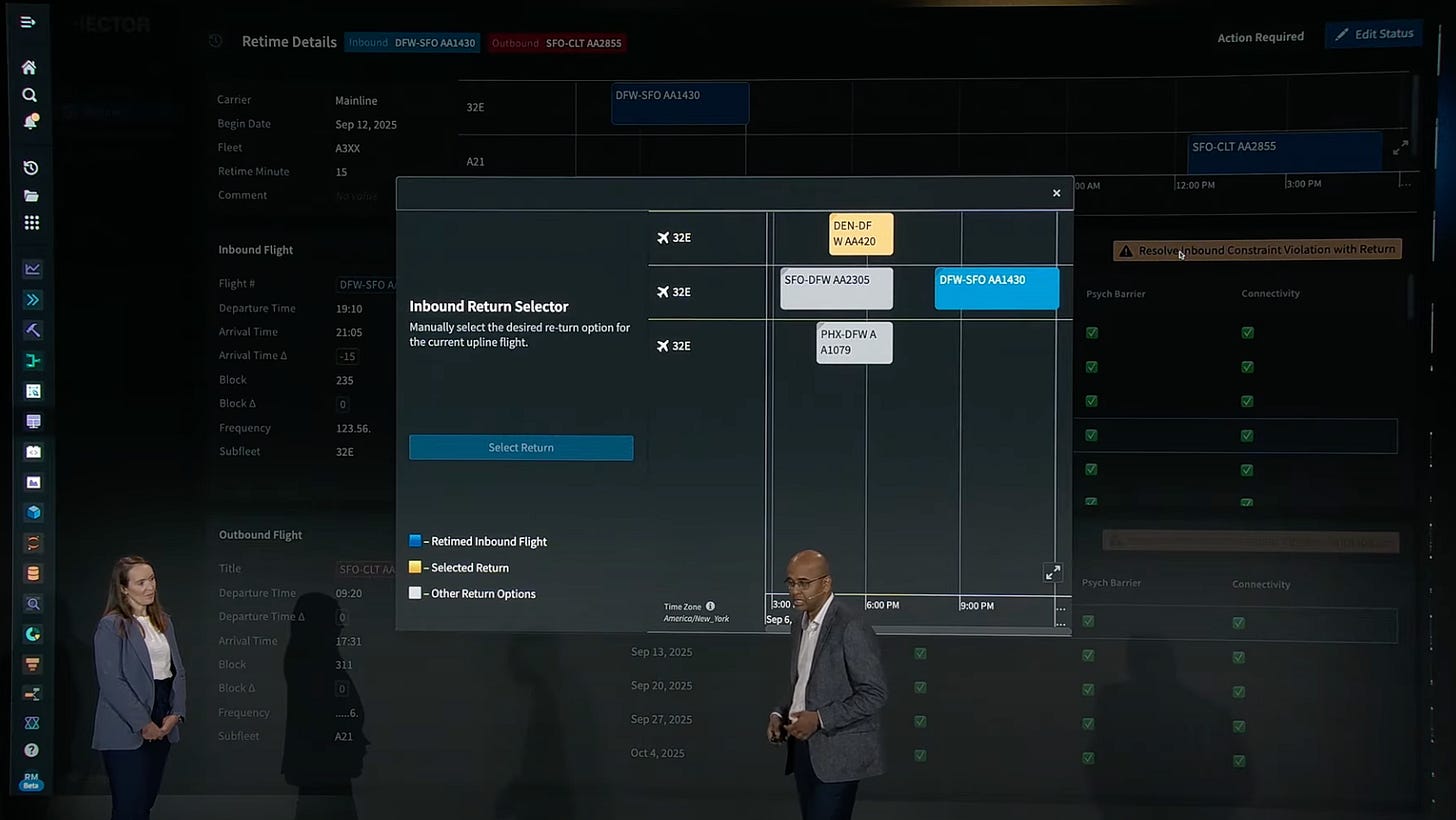

A canonical example from the session: an inbound to San Francisco arrives late in the evening; the next-day morning outbound departs so early that the same crew cannot legally operate both due to rest rules. Without early detection, you end up paying for an extra layover day and ferrying in a different crew—classic leakage of time and money. Vector detects these patterns across the network, flags them, and proposes remedies (e.g., retime a flight by 15 minutes)—while simultaneously estimating the upstream/downstream blast radius of that change.

That “15 minutes” is the telling detail: retimes are deceptively simple. In practice, a single change can violate gate availability, turn-time standards, airport “site barriers,” maintenance windows, or crew legality elsewhere in the chain. Vector’s value isn’t proposing the obvious; it’s validating the non-obvious constraints and shepherding schedulers toward a net-feasible solution.

The Technical Loop: From Detection to Decision

From the demo narrative, you can reconstruct Vector’s core loop as four interacting components:

Detection (Advisor)

Background models continuously scan the entire schedule for inefficiencies—duty-time conflicts, fragile turns, mis-flows—and surface them as ranked recommendations. This flips the task from manual “hunt and peck” to guided triage.

Local Feasibility Checks (“Live Checks”)

When a scheduler previews an edit (e.g., retime flight X by 15 minutes), Vector runs real-time constraint validation: Are we creating a gating conflict? Violating turn standards? Breaching airport site barriers? Breaking crew legality or maintenance requirements? These checks run continuously as the user interacts, so infeasible moves are flagged before they become latent defects.

Optimization Proposals

If a proposed change introduces new conflicts, Vector doesn’t just throw an error. It suggests alternative flows—for instance, subtly re-flowing lines to keep legality while preserving profitability. Users are guided through a solution space that balances local fixes with network-level coherence.

Network Stress Simulation (“Blue-Sky vs Gray-Sky”)

Before publishing edits, Vector runs network simulation to stress-test outcomes under disruption (e.g., thunderstorms). This is crucial: a schedule that looks good in deterministic conditions can collapse under variance. The simulator identifies choke points and recommends supplemental edits to increase robustness, all before changes are committed.

Together, these components form a closed-loop, human-in-the-loop optimizer: models propose and validate; humans arbitrate tradeoffs; simulation verifies resilience. The system’s purpose is not to fully automate scheduling, but to compass expert planners toward the best moves quickly and safely.

Why the Approach Works

Continuous, not sequential. Traditional planning cascades from network to ops in slow hand-offs. Vector collapses those workflows, allowing edits to be evaluated end-to-end while they’re still cheap to change.

Constraint-aware by construction. Feasibility checks aren’t a post-hoc audit—they operate inline with user actions, which prevents “solution ping-pong” between teams.

Optimization that respects reality. The system blends recommendations (detection) with mathematically grounded alternatives (optimization proposals), ensuring that “fixes” don’t just shift problems elsewhere.

Robustness, not just profitability. Stress simulation enforces a standard that schedules must operate on both blue-sky and gray-sky days. Resilience is treated as a first-class objective, not an afterthought.

Measured impact. Within ~one year, the program has generated tens of millions of dollars in benefits—evidence that the integrated, model-assisted workflow is unlocking previously hidden value.

A Closer Look at Constraints Vector Watches

While the session didn’t enumerate every rule, it spotlighted several classes that Vector checks in real time:

Crew legality & rest (e.g., minimum rest windows between duty periods)

Gate availability & gating conflicts

Turn-time standards (can the aircraft be turned safely and on time?)

Airport site barriers / local operating constraints

Maintenance windows and requirements

By running these as live checks, Vector ensures each micro-edit remains compatible with the macro-plan.

From Crew to Enterprise Planning

The live demo centered on crew-driven inefficiencies, but the program’s explicit goal is to expand Vector from a network+crew surface into an integrated planning platform that encompasses workforce, workload, materials, ground equipment, and maintenance planning. The thesis: many “local” wins materialize only when all plans are co-optimized, and many “local” losses are avoidable once the entire planning stack is visible in one place.

What This Means for Practitioners

If you lead scheduling, crew, or ops planning, the Vector story suggests a few implementation principles:

Expose the whole constraint graph to users. Don’t just block infeasible moves—explain the violated constraint and propose feasible alternatives.

Prioritize proactive detection. A recommendation queue (ranked by value at risk and feasibility) shifts effort from reactive firefighting to front-loaded optimization.

Always simulate before you celebrate. Reliability is a distribution, not a point estimate. Bake disruption models into the accept/publish step.

Keep humans in the loop. Scheduling is a landscape of tradeoffs. Use models to shrink the search space and quantify the side effects, but let domain experts adjudicate.

Measure, then scale. Start with a narrow domain (here, crew + retimes), track realized value, and only then generalize to adjacent planning functions.

The Bottom Line

American Airlines is turning network planning from a sequential, email-driven exercise into a continuous, model-assisted decision system. Vector’s architecture—detection, live feasibility checks, optimization proposals, and stress simulation—doesn’t just make a schedule; it helps make the best schedule that still works when the weather changes. That is how you convert planning from a bottleneck into a competitive advantage—and why the team is confident about scaling the platform across the rest of operations planning.