Maximizing Productivity and Efficiency through Supply Chain Optimization (Part 2: A Palantir Case Study)

Pre-Show | AIPCon 7 Part 2

In the last post, we discussed the first case study of the pre-show, Tampa General Hospital. By building an ontology layer for patient information, it was possible to create a "modern hospital OS" that combines multiple solutions, including a patient information sepsis response hub, treatment and management, patient placement, and bed planning. This reduced the cognitive burden on the various members of the hospital team and increased overall hospital operational efficiency.

In this article, we'll take a look at the second example, the case of Land O' Frost.

The full article is available at this link, as it was too long to include in this email!

Interested in cooperation with Morph Systems? Contact us at mingyupark@morphsys.ai

Land O' Frost

Land O' Frost is a third-generation, family-owned and operated lunch meat packaging company, with sausage products and natural specialties such as the Wellshire brand sold at Whole Foods, Sprouts, and more. It has operations across the United States.

Land O' Frost has a strong focus on optimization, and while in the past they've put a lot of effort into automating equipment, they're now focused on streamlining internal processes. They're working with Palantir on three practices - Master Planning, Finite Scheduling, and Clear to Build - that they estimate will save them about 70 to 80 hours of work per week.

Master Planning

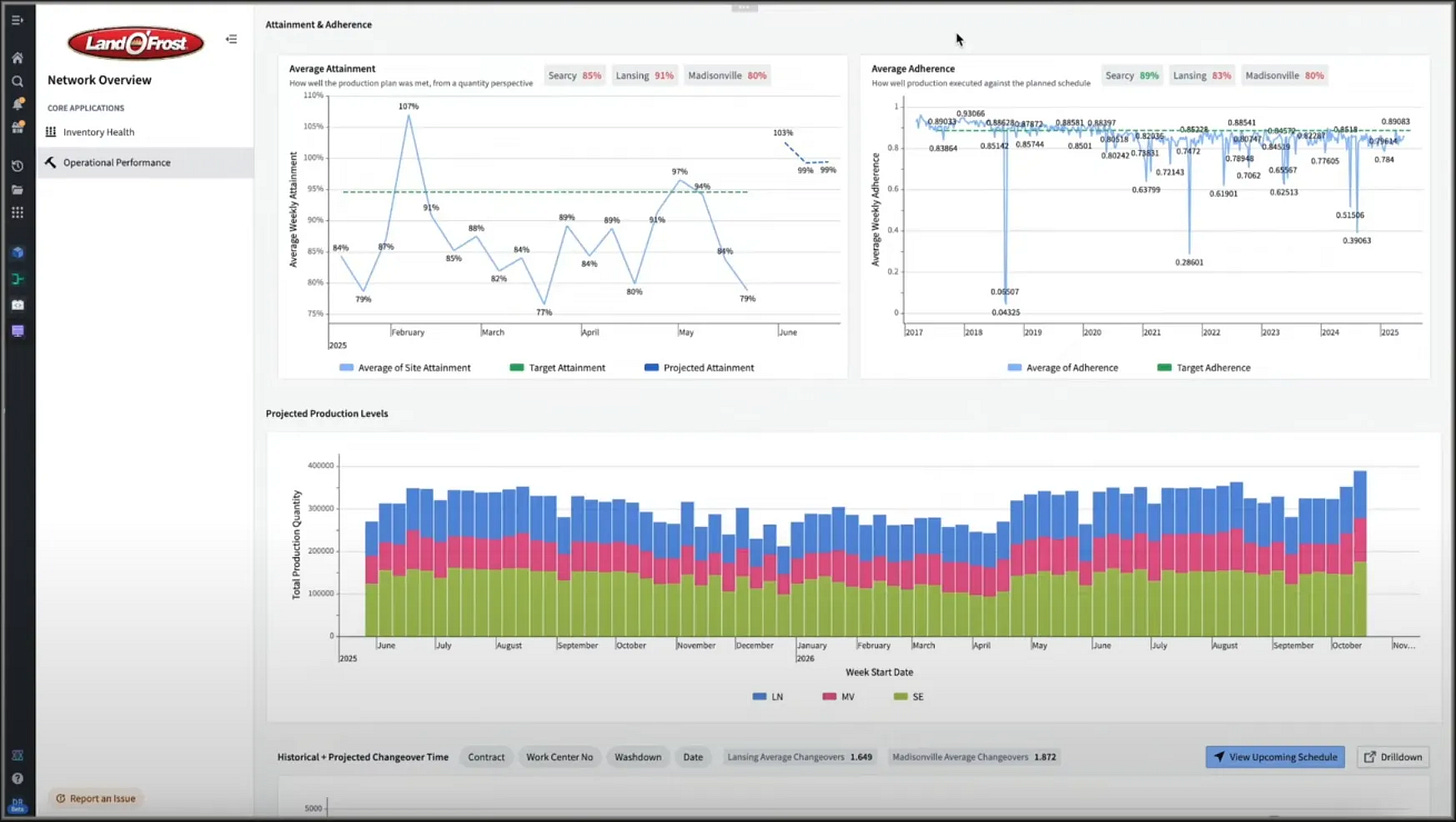

In the past, everything was done manually in Excel (downloading from the ERP system and generating reports), but now the company utilizes dashboards that allow management and the master scheduling team to see the status of customer order fulfillment in real time.

The dashboard shows everything from customer service levels, inventory levels, etc. in real-time data, graphed on the foundry through Quiver, so there is no longer a need to download and analyze data, and the real-time data is immediately available.

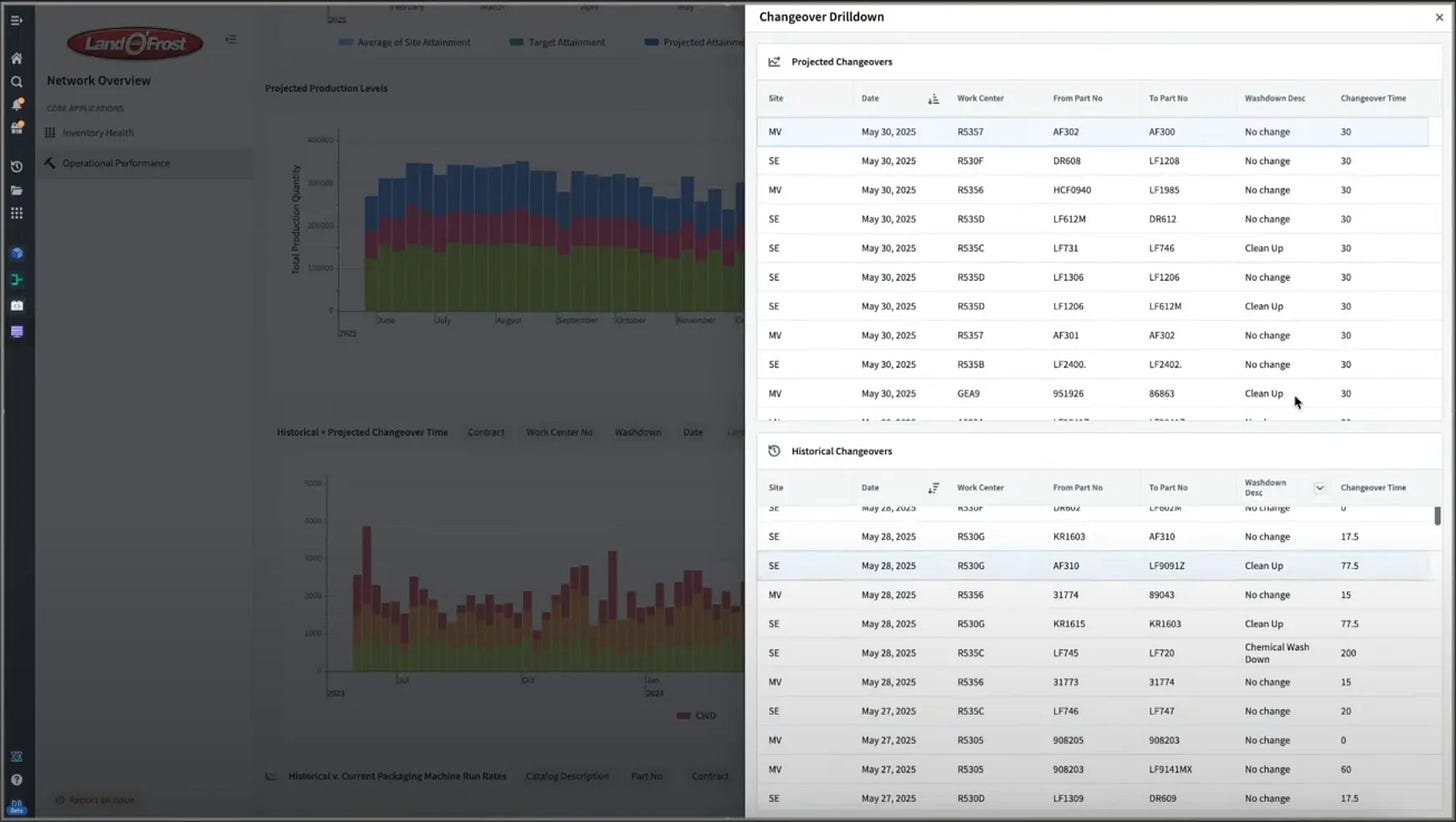

The master scheduling process allows them to generate production schedules up to 18 months in the future. Creating an annual operations program used to take about 40 hours, but now takes about 30 minutes. Optimization in the manufacturing plant focuses on reducing changeovers, and the dashboards they've implemented make it easy to see the reduction in changeovers.

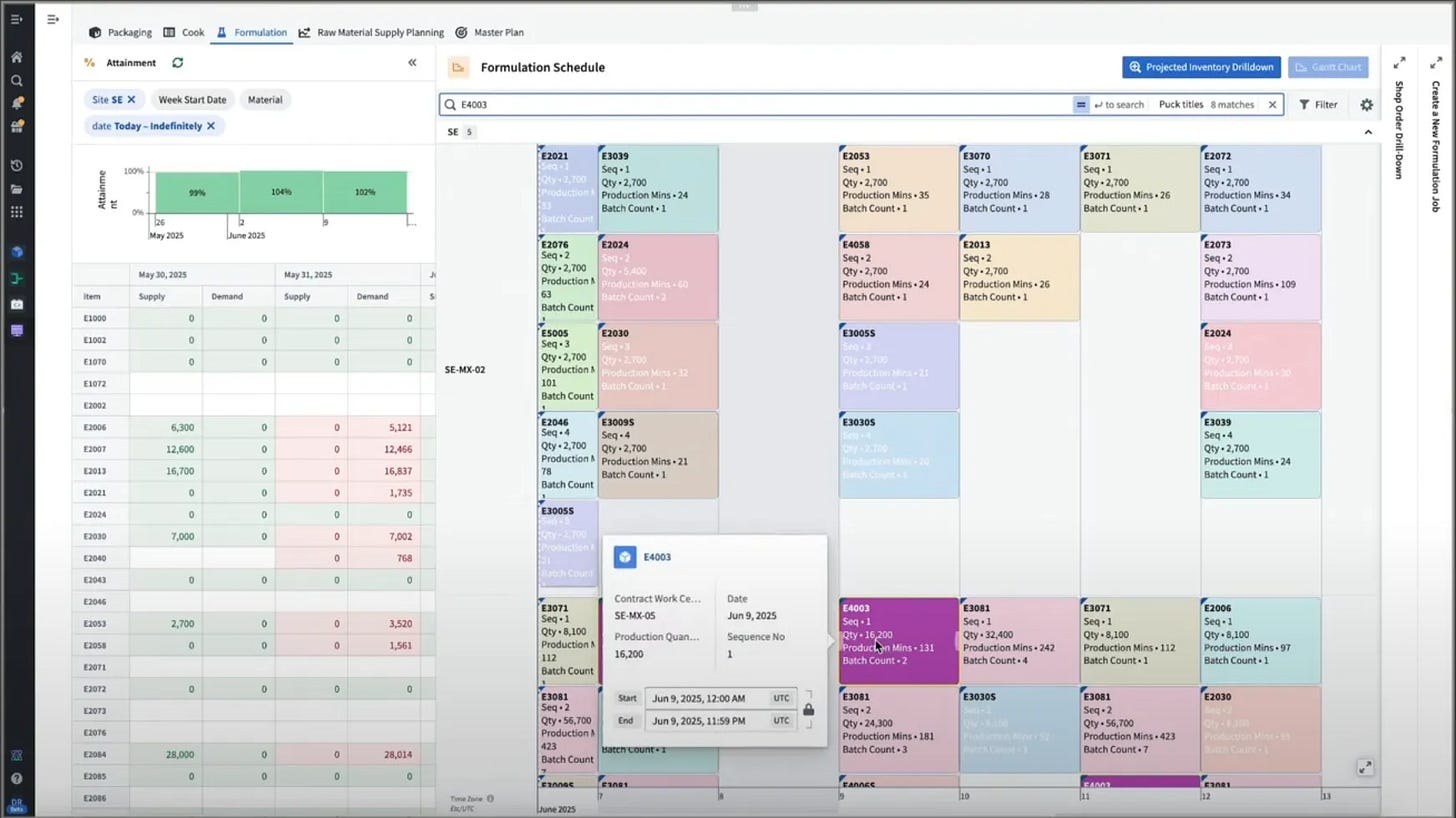

Finite Scheduling

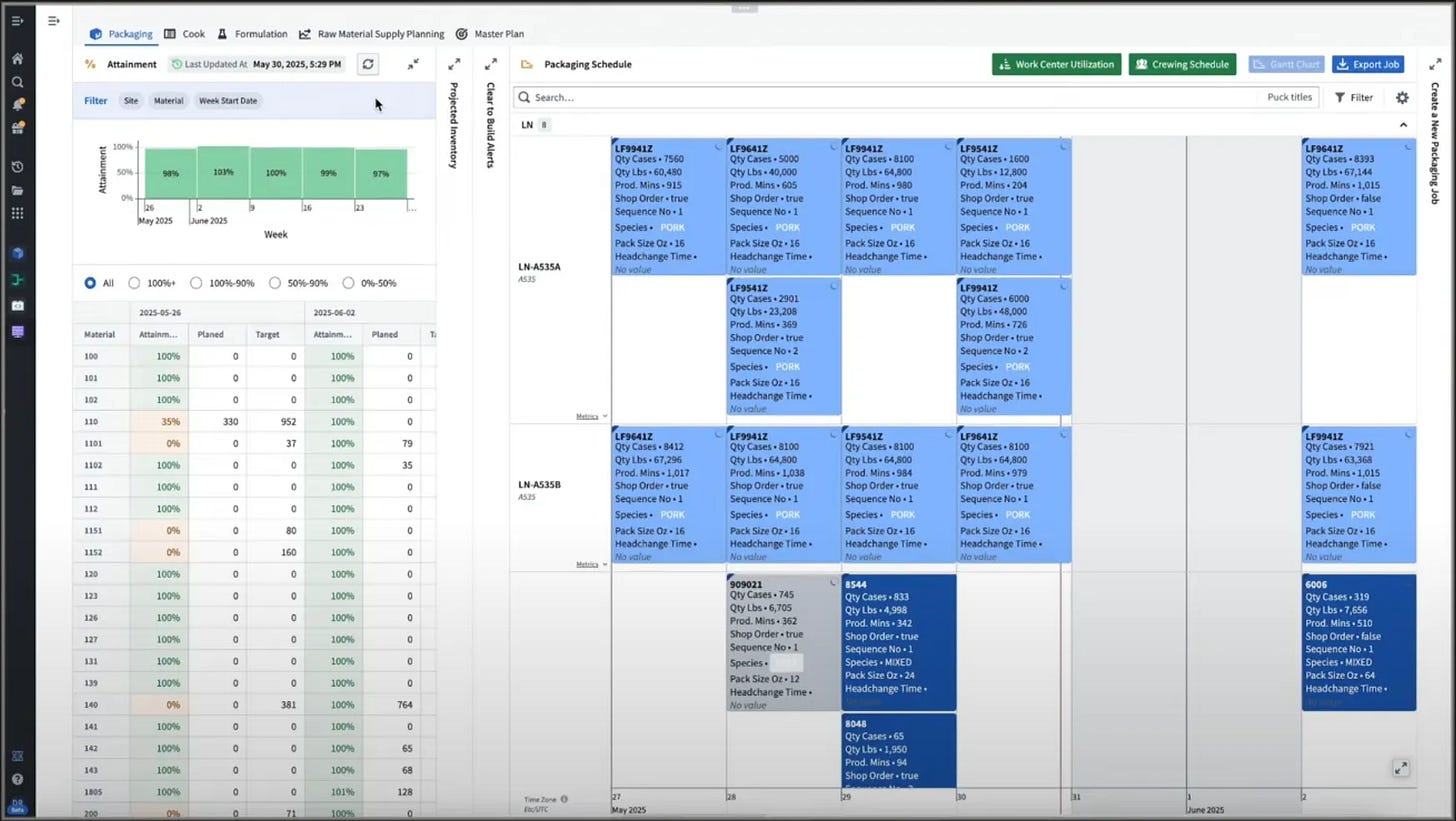

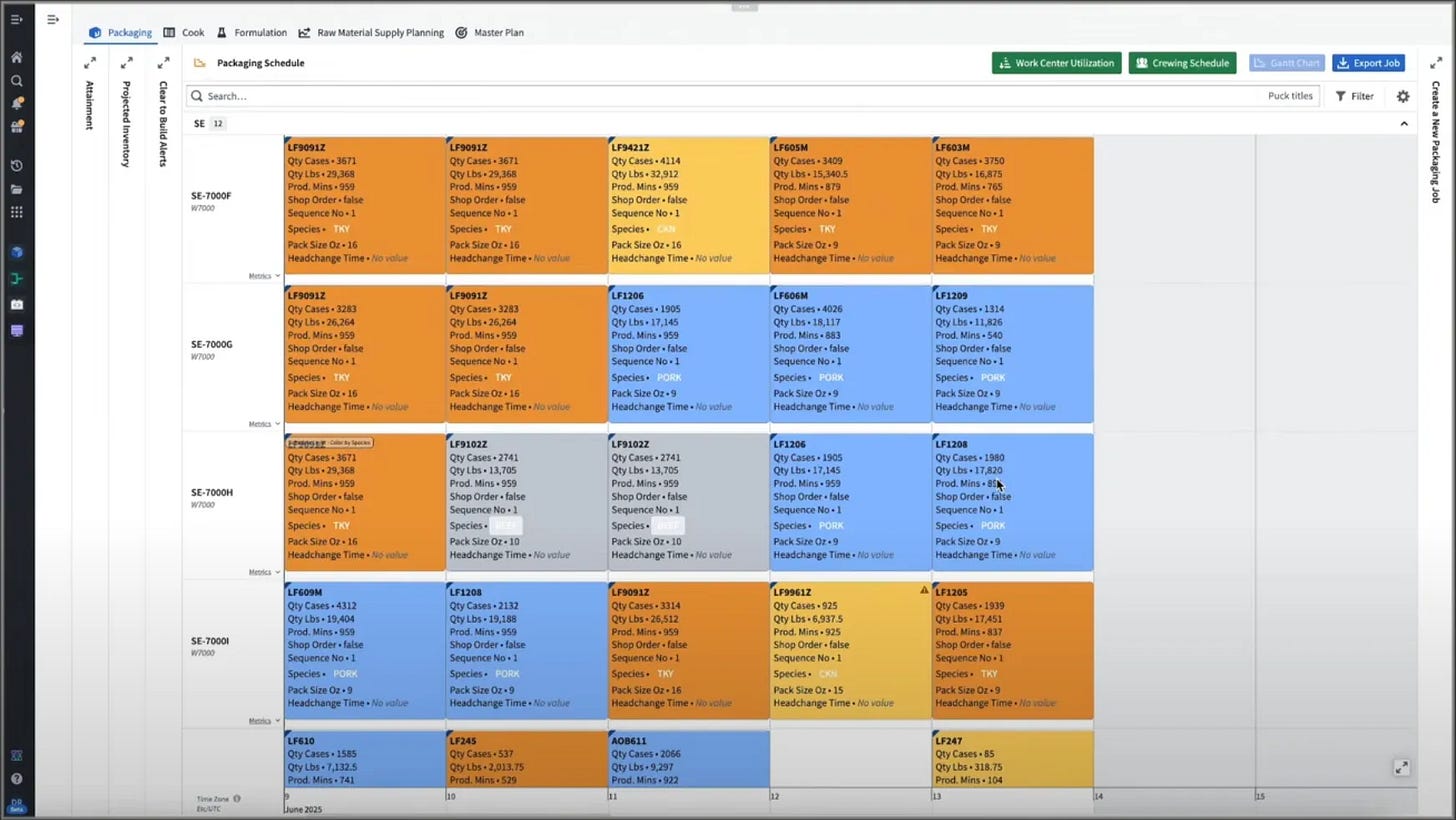

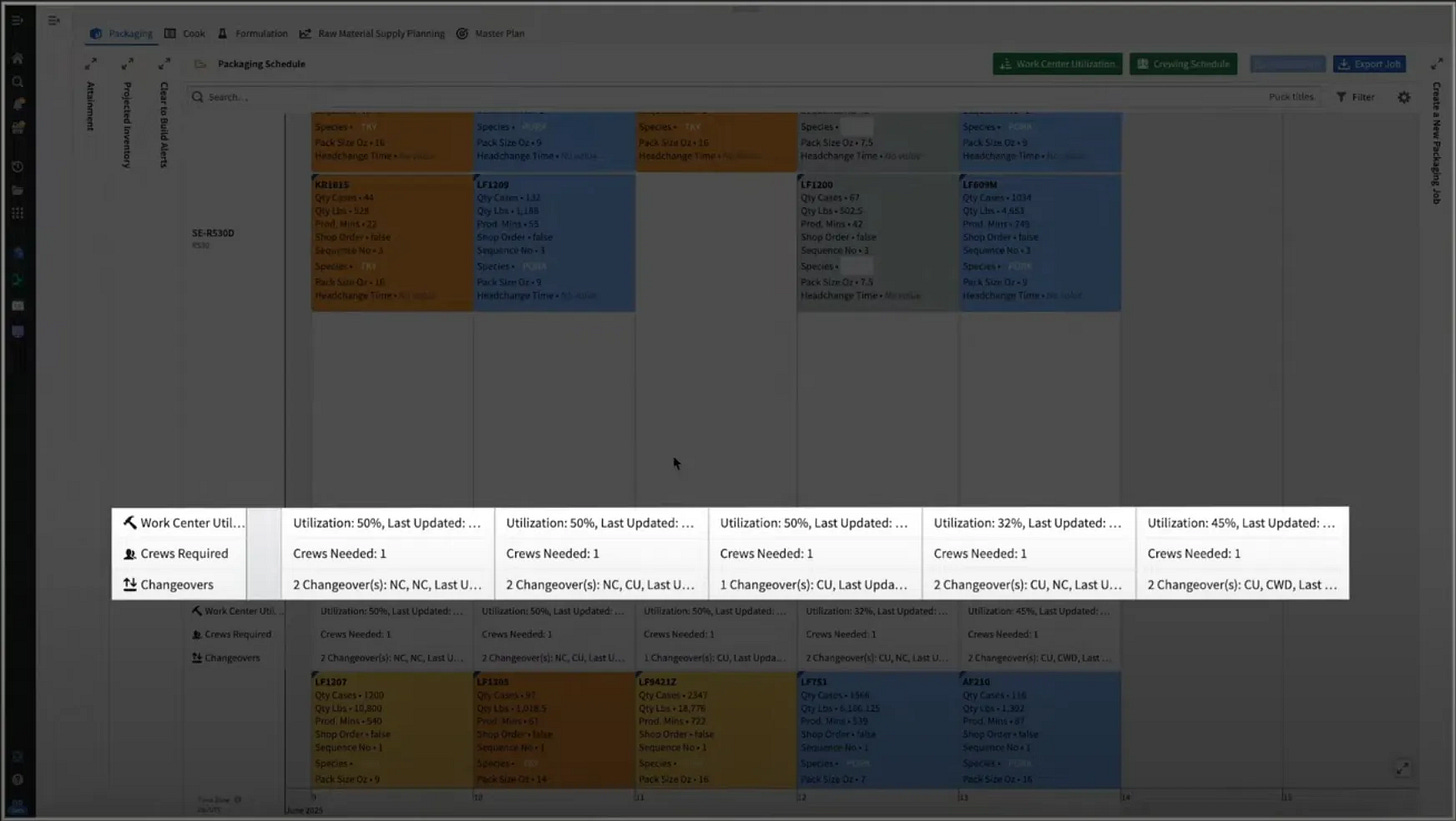

The master schedule specifies that a particular product is to be produced in a particular factory in a particular week, and the manufacturing team decides which lines to produce on which days and in what quantities. Visual elements called "pucks" in the system represent the production plan, and these pucks move together when the production schedule changes due to raw material delays. This can be implemented through dynamic scheduling on the foundry and the Contour dashboard.

The meat processing industry has specific production sequencing constraints. For example, producing pepper turkeys first can cause pepper to be mixed into other items, so these sequencing constraints are built into the tool. The vast knowledge of employees who have been with the organization for more than 40 years is incorporated into the tool, so when a new employee comes in, they don't have to refer to spreadsheets or post-its, all the information is built into the tool to create an optimized plan.

When planning, the tool can identify the number of workers needed on a particular line, the number of transitions (one, two, five, etc.), and the number of times they need to make a changeover. Planners can move the "puck" to place certain items on a different day or in a different order, with an error message if they are moved in the wrong order.

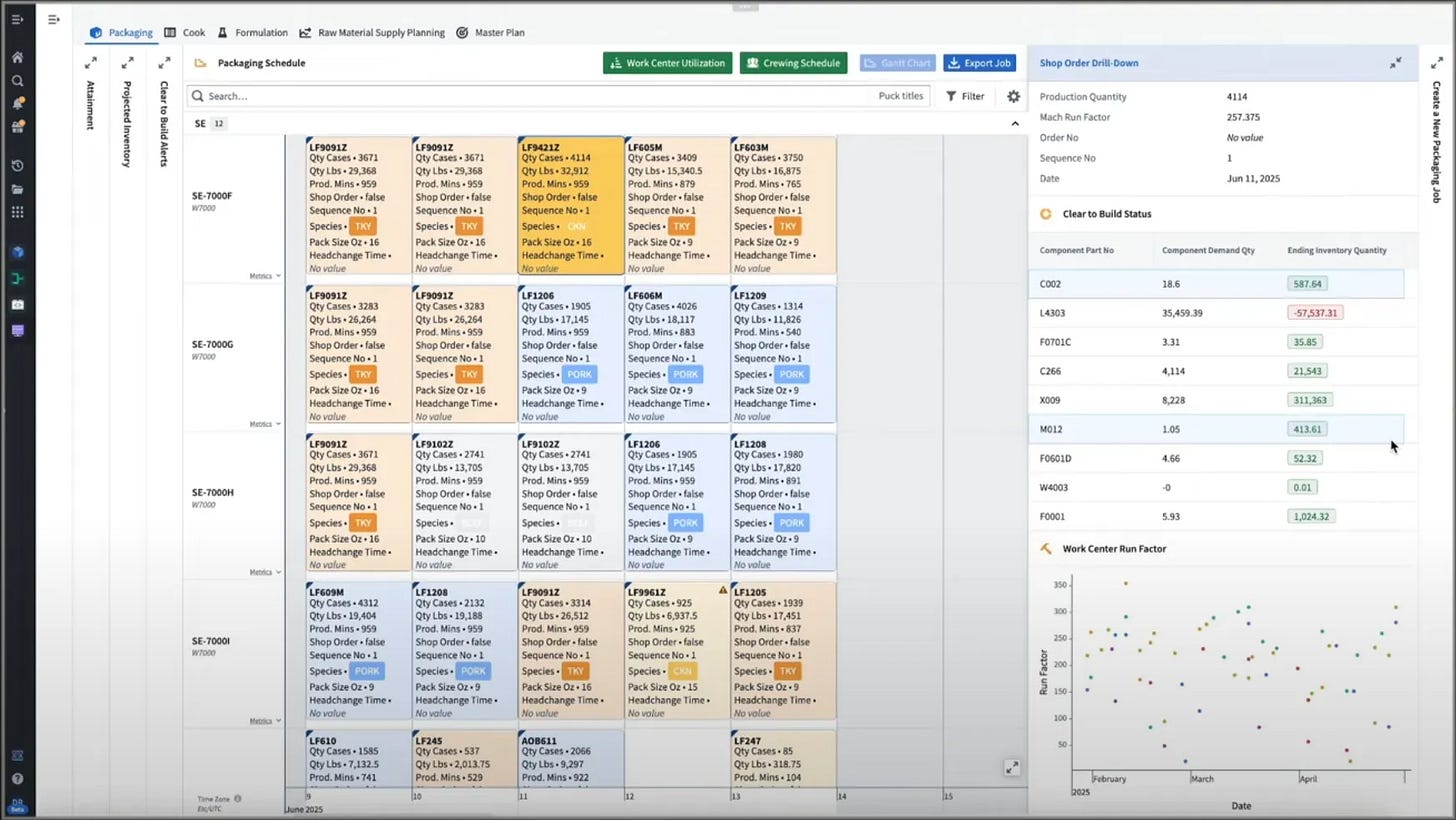

Clear to Build

By clicking on a specific inventory management unit, you can see the historical run rate of all the machines that produced that item in the last 90 days. When moving the "puck" to different lines, planners can choose the most efficient line based on historical data, which is more accurate than relying on knowledge that may be inaccurate. For example, if a particular ingredient is in red because it is low in stock, you can get a full picture of when it will be cooked and available to support production.

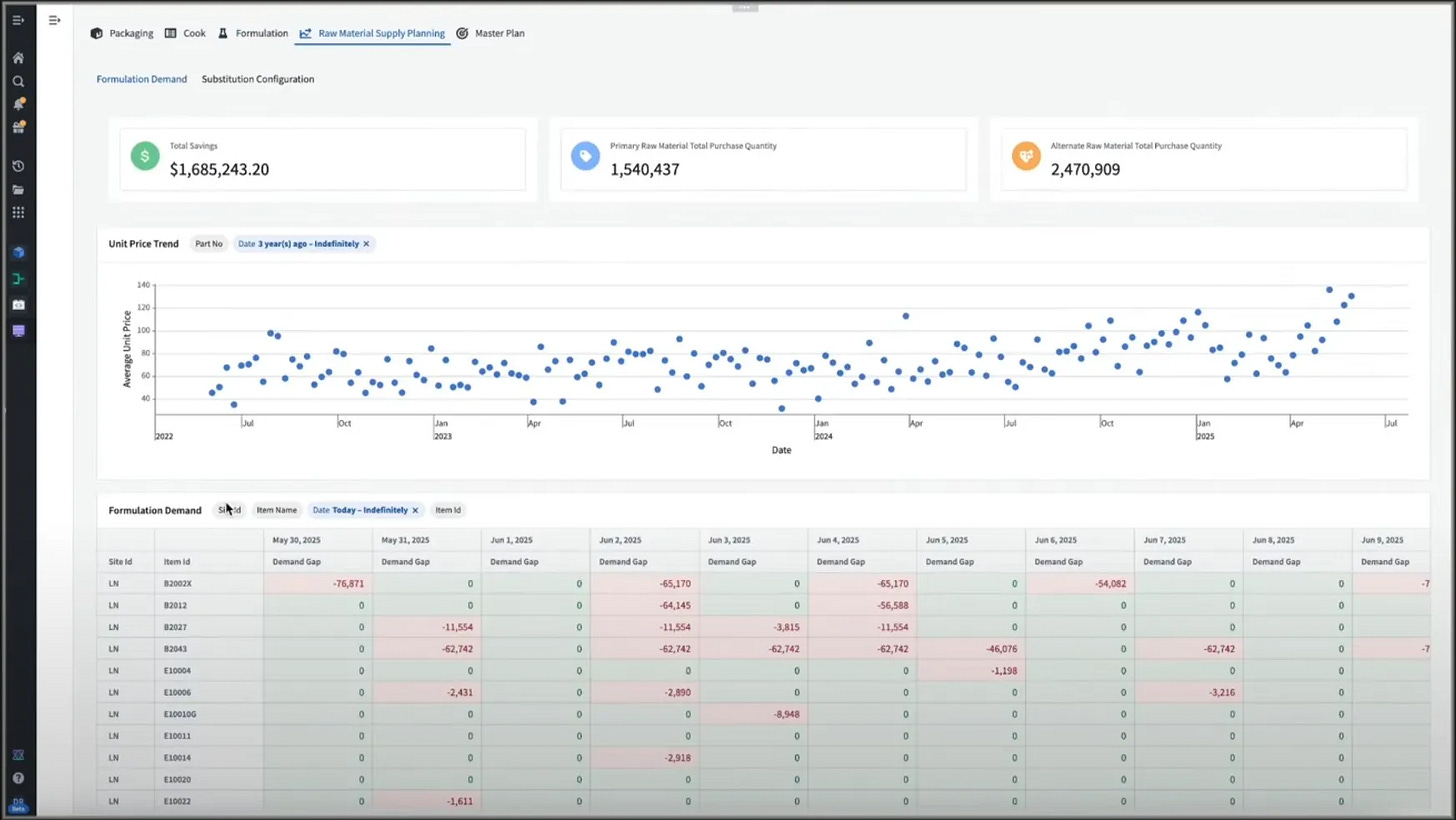

The system covers the entire production process, not just packaging, but also cooking schedules, filling schedules, emulsification schedules, etc. Ultimately, it even links to raw material purchasing, providing opportunities for cost savings.

AIP Platform

During the AIPCon 7 pre-show, we saw one Palantir AIP platform supporting industries as disparate as healthcare and food manufacturing. Tampa General Hospital is building a "connected care" operating system with ontology at its core to automate bed assignments, patient journeys, and staffing, reducing wait times and resources, while Land O'Frost is improving planning quality by reducing production and packaging scheduling from hours to minutes.

Best of all, Palantir's approach is designed so that the software adapts to the customer's operations with ontology-based workflows, rather than the user adapting to the software, and we're seeing these customized workflows deploy rapidly, often within weeks or months.

Both examples also illustrate the connection of operations beyond the connection of data, where iterative use cases centered around the performance of individual solutions create the overall cumulative value of the connection. In both cases (better patient outcomes in healthcare and reliable food production and supply in manufacturing), we saw the power of connecting data and solutions on top of the AIP platform.